One of the first things most people notice when they get their first set of lock picks is that their kit typically does not come equipped with many turning tool options. Fortunately, turning tools are the easiest tools to make yourself.

Why do you need multiple turning tools?

Bottom vs. Top of Keyway

The most common turning tool is used in the bottom of the keyway, and therefore called a “bottom turner.” The business end that enters the keyway is typically around 1/2″ (12mm). If you’re picking a lock with a very short keyway, you may not have the room for a turning tool and your pick to fit below the keypins. In this instance, you would choose a top turning tool. These tools have a shorter end, typically 1/4″ (6mm).

Thickness

Having a variety of thicknesses of turning tools can improve your turning force accuracy and tactile feedback. A turning tool that is too small or loose in a keyway can slip and ruin any progress you’ve made. This is especially true for top turning tools. The general rule of thumb is to use the thickest turning tool that easily fits in the keyway, either bottom or top.

Making your own Turning Tools

Tools and Materials

- Cutting Tool – You can use anything that cleanly cuts steel without heating it (heat can ruin the temper of some types of steel and make it weaker and prone to breakage, so don’t bend it until it breaks). Hacksaw, Dremel tool, or the Cadillac of cutters the HK Porter Cable Cutter (Full disclosure: LockEx gets a small percentage of sales through Amazon’s referral links.)

- File and Sandpaper – A bastard file is very handy for shaping your turning tools, especially when tapering the flat end of a thick turning tool so that it fits into the keyway like a wedge. You can also use 120 grit sandpaper.

- Bending Tool – Vice grips, pliers or a vice.

Turning Tool Stock

The best quality and most easily sourced turning tool stock are stainless steel windshield wiper blade inserts. You can find them in almost any auto parts store garbage can. Harvesting used windshield wiper blade inserts is easy if you follow these steps:

- Grab the rubber wiper blade at one end and peel it off the blade.

- Carefully remove the two inserts held in the blade assembly. Be careful, the ends of the inserts are sharp and will cut your fingers.

Turning Tool Fabrication

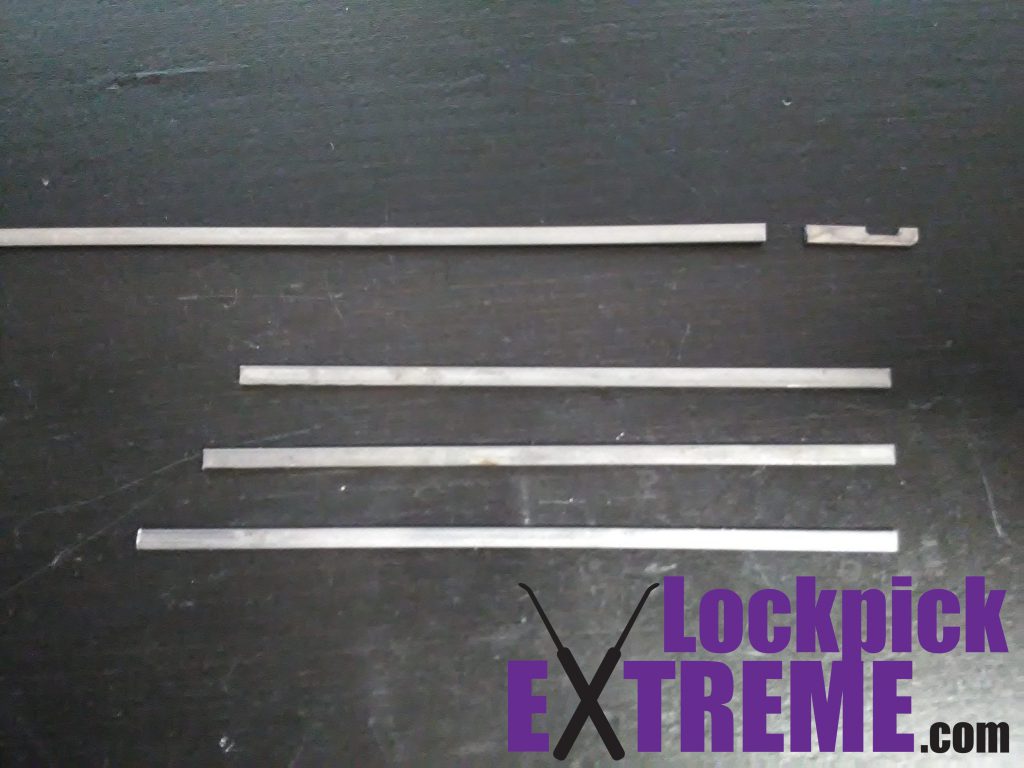

- Trim the notched end of the wiper blade. then cut sections 3 1/4″ (83mm) for a 1/4″ (6mm) top turning tool, 3 1/2″ (89mm) for a 1/2″ (12mm) bottom turning tool and 3 3/4″ (92mm) for a combination top and bottom turning tool.

Different cuts of an insert. - File or sand the cut ends so they are not sharp and won’t cut you, your clothing, or the case you store your picks in. Be careful to not round the corners too much, a rounded turning tool is more likely to slip out of the keyway.

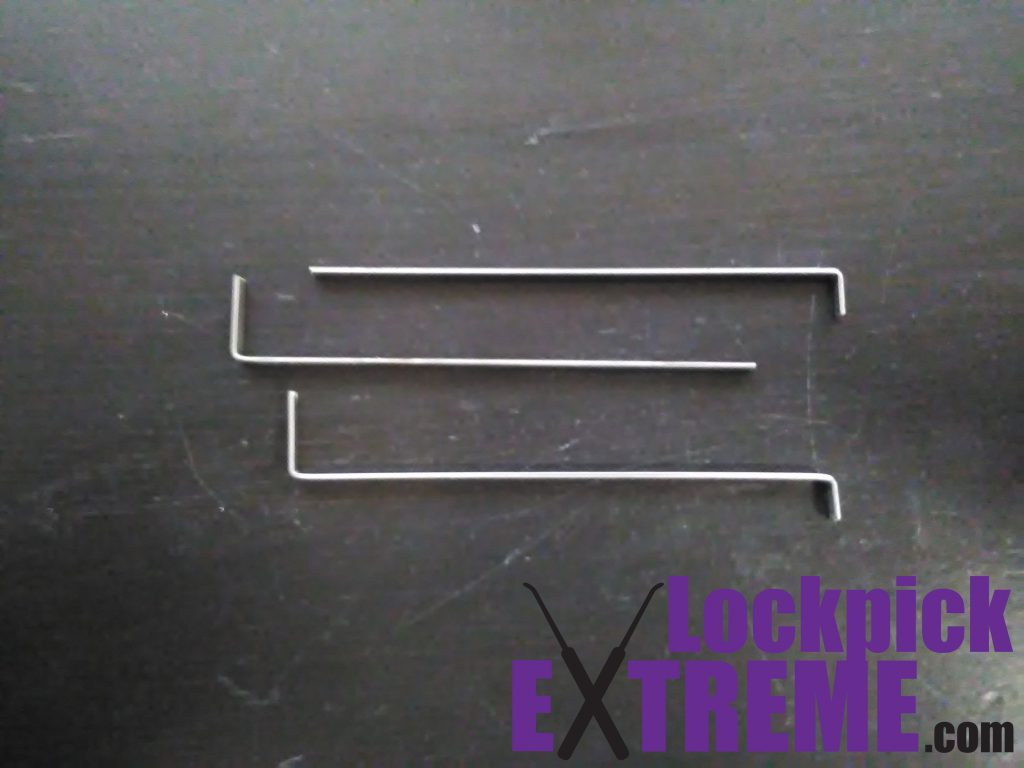

- Bend the ends at a 90-degree angle to 1/4″ (6mm) for the top turning tool and 1/2″ (12mm) for the bottom turning tool. Not all stainless steel windshield wiper inserts are the same thickness, quality, or have had the same treatments applied. Some inserts may be more prone to breaking, splitting, or cracking when bent so do this process slowly to minimize any potential damage.

Knowing how to create your own turning tools opens up a huge opportunity for customization and personalization. Because all locks are unique, you may find that the best turning tool doesn’t come standard in the kit you purchased. This skill will allow you to create an infinite variety of tools and also take pride in something you made by hand.